Tips, Tools & Techniques eNote #31

Loose Tenon Joinery, Part 4: Tenons

Time for tenons! See how easy it is to make custom fit tenons. By making the tenons slightly smaller you not only add a gap for glue, but it also allows some adjustment when it comes time to glue up your workpieces.

Loose Tenon Joinery, Part 1: https://www.thewoodsmithstore.com/tips-tools-techniques-enote-28/

Loose Tenon Joinery, Part 2: https://www.thewoodsmithstore.com/tips-tools-techniques-enote-29/

Loose Tenon Joinery, Part 3: https://www.thewoodsmithstore.com/tips-tools-techniques-enote-30/

FEATURED PRODUCTS

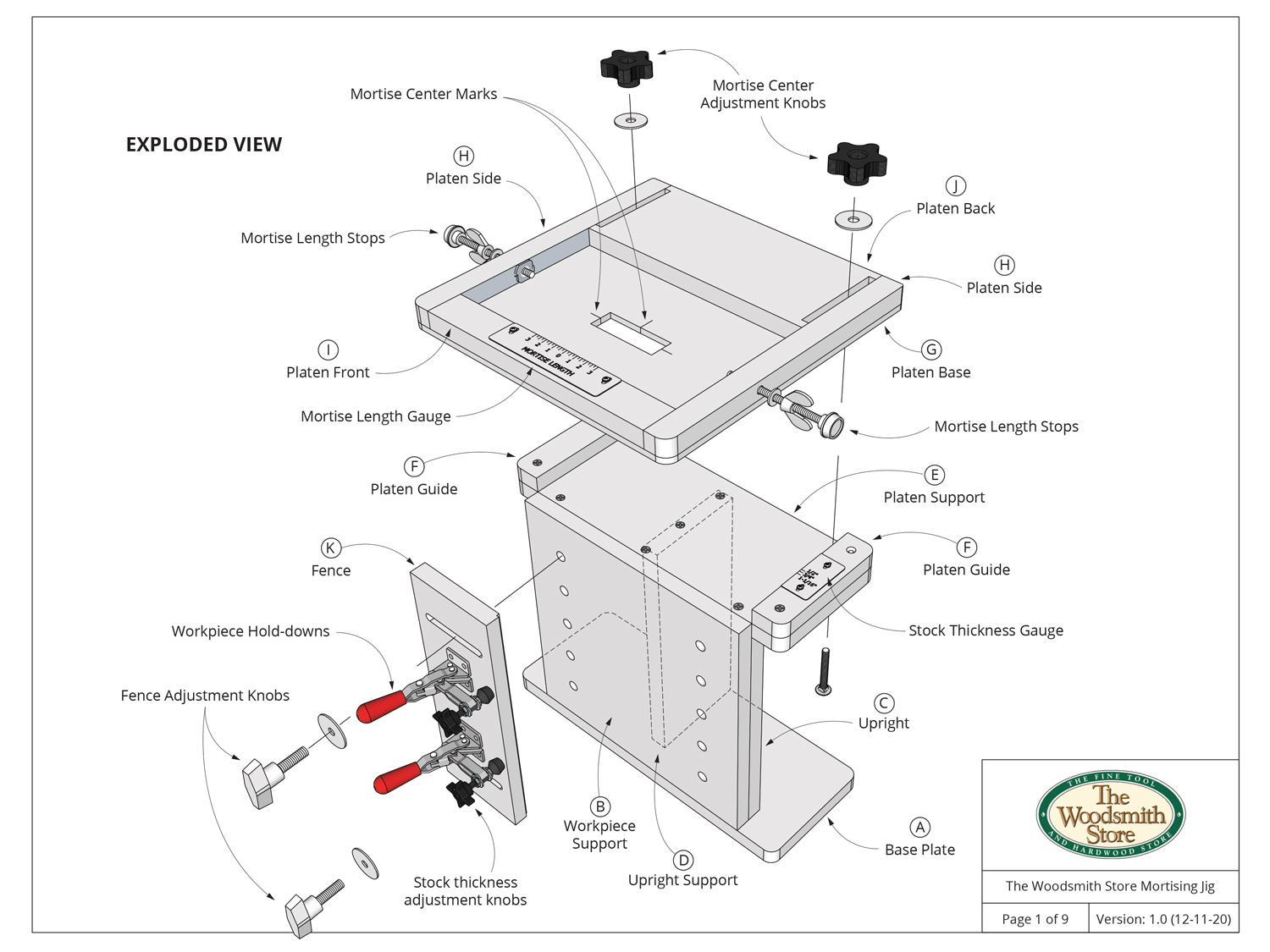

Router Mortising Jig Dimensioned Drawings

Looking for an easier way to cut mortises? Try this shop-built benchtop mortising jig. When mated up with a plunge router and a solid carbide straight bit, this jig will cut 1/8″ to 1/2″ mortises in stock thickness from 1/4″ to 2-1/2″ thick, up to 3-1/2″ long. It’s a perfect solution for loose tenon joinery. The dimensioned drawings include an 9-page plan with exploded views, parts views and a one page bill of materials and supply list.

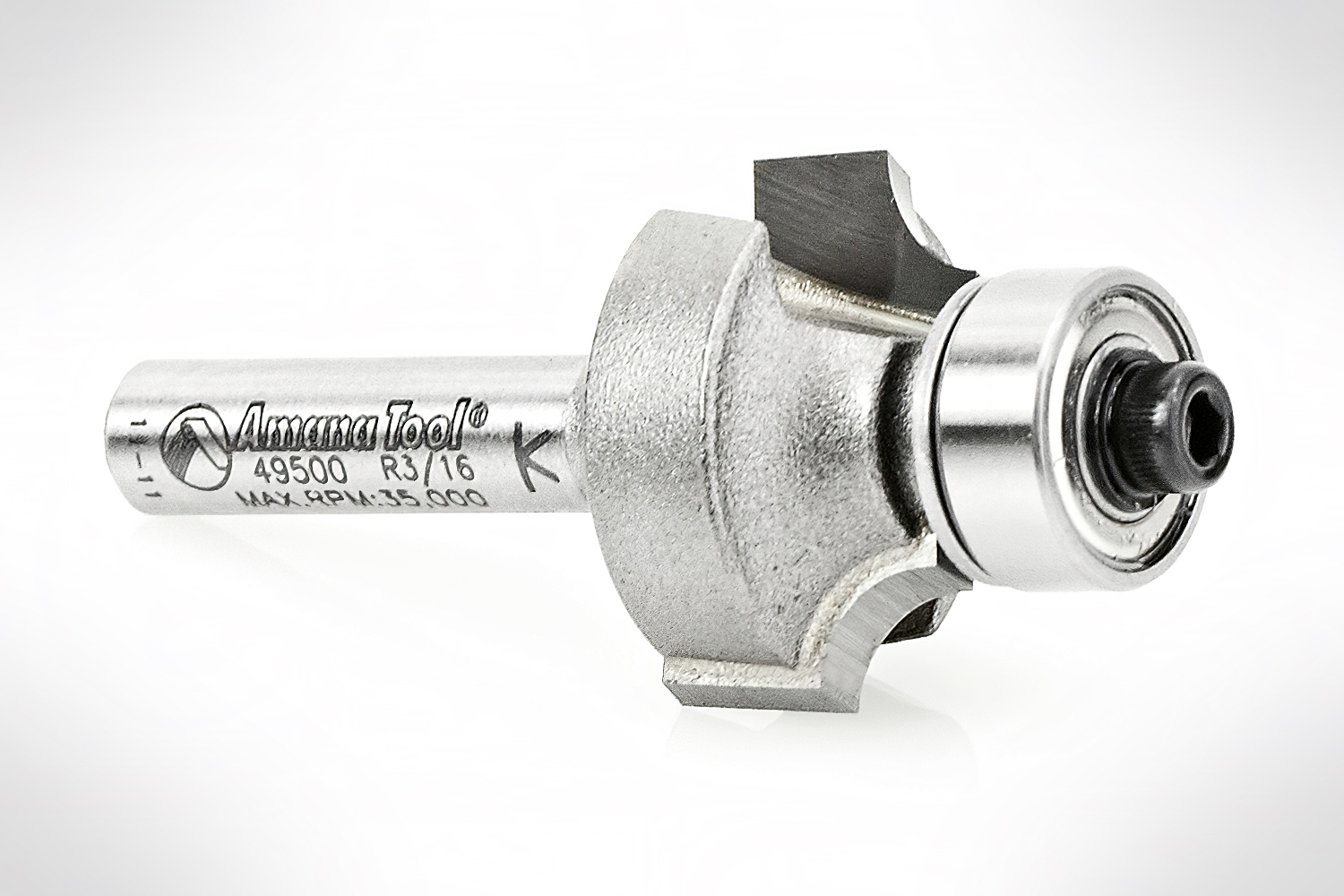

3/16″ Amana Round-Over Bit, 1/4″ Shank

The Amana Carbide-Tipped 3/16” Radius Corner Round bit is the basic edge-forming bit. The bit rounds an edge to a given radius. The tool is shouldered to cut a fillet. The cut can be used to ease edges, as a simple profile, or as a part of a complex one. Also known as round-over, rounding over and quarter-round. If a smaller pilot bearing is used, a second shoulder can be produced, in effect making the bit a beading bit.

Visit the Store in Iowa

Visit the Store in Iowa