Make safer rip cuts on a table saw with feed rollers

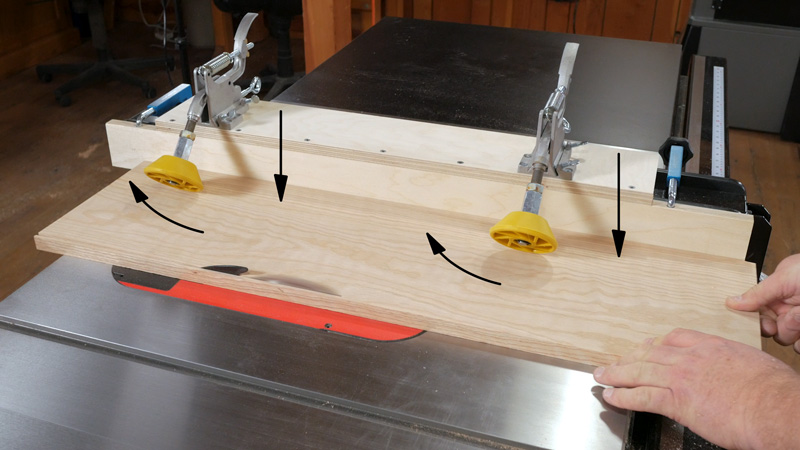

Ripping a workpiece to size on a table saw is much easier when you have a good way to hold the workpiece down. This feed roller set provides downward pressure as well as inward pressure towards the fence as you rip the workpiece.

Make safer rip cuts on a table saw with feed rollers

The rollers simply mount on top of the table saw rip fence. You easily mount them by creating an L- shaped or U-shaped axillary fence made from ¾” plywood.

Make safer rip cuts on a table saw with feed rollers

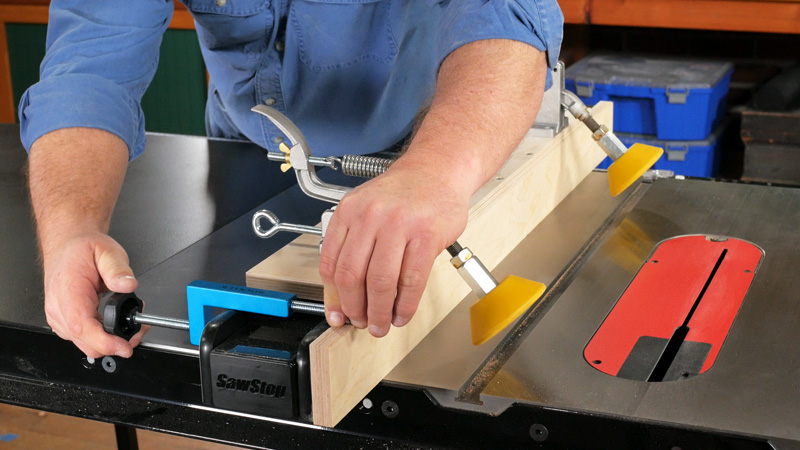

A set of universal fence clamps holds the L-shaped auxiliary fence in place. The clamps shown here are fully adjustable for most fence widths.

Make safer rip cuts on a table saw with feed rollers

The universal fence clamps require a 3/8” hole drilled at both ends for the clamp to fit into. Drilling the holes on the drill press with a handscrew clamp keeps the holes perfectly aligned.

Make safer rip cuts on a table saw with feed rollers

Once the holes are drilled you can mount the auxiliary fence and roller assembly onto the table saw fence with the universal fence clamps.

Make safer rip cuts on a table saw with feed rollers

To use the rollers simply adjust the height of each roller about 1/8” to 1/4” below the face of the workpiece. You can also adjust the rollers from side to side as well.

Make safer rip cuts on a table saw with feed rollers

As you feed the workpiece each roller applies a small amount of downward pressure. It also pulls the workpiece slightly towards the fence, keeping it aligned with the cut.

Make safer rip cuts on a table saw with feed rollers

The rollers roll easily so feeding the workpiece through the table saw blade is smooth, easy and most importantly, safe!

Visit the Store in Iowa

Visit the Store in Iowa